|

TC8418 (MCH13A) is a high-performance mold steel developed by steel mills using the latest developed process technology. This process technology has surpassed many advanced production technologies in the production of high-performance special materials, and has made significant breakthroughs in controlling the purity, uniformity, and grain microcrystallization of the matrix structure. The technical performance of various special materials produced using this process technology has reached and exceeded the international advanced level. We use this technology to produce high-performance hot work mold steel TC8418, and its various technical indicators have also reached and exceeded the advanced level of international famous brands. It has high purity, uniform structure, and ultrafine grain crystallization, making the material have extremely high toughness in all directions. It has good resistance to annealing and high temperature strength, excellent hardenability, and especially outstanding resistance to thermal cracking and life cycle that surpasses imported materials.

Can be widely used

Die casting: can be used for aluminum and copper alloy die casting of automotive, motorcycle engines, and various automotive accessories.

Hot die forging: Hot die forging of automotive engine connecting rods, precision gears, etc.

Extrusion mold: Various aluminum and copper alloy profiles are extruded.

| Chemical composition and other indicators |

|

C

|

Si

|

Mn

|

Cr

|

Mo

|

V

|

p

|

s

|

Other elements

|

|

0. 33-0. 37

|

0. 15-0. 5

|

0. 15-0. 5

|

5. 0-5. 5

|

2. 4-2. 6

|

0. 4-0. 6

|

0. 015

|

0. 003

|

Not yet announced

|

Hardness: Soft annealing ≤ 180HB

Non metallic inclusion: Class A, B, C, D ≤ Class 0.5

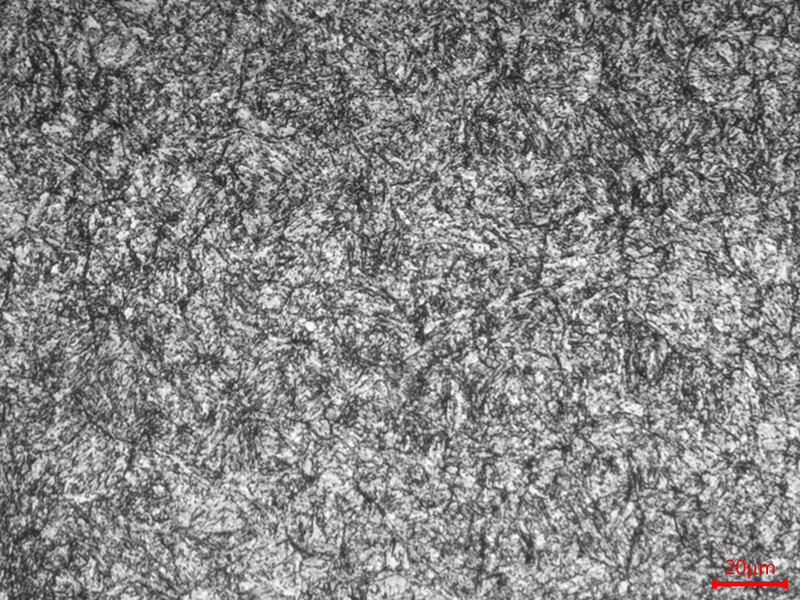

Grain size:≥Level 9, normal value level 10

Annealed microstructure:〜A2、B1

U-shaped impact toughness value (at room temperature):≥50J

Horizontal to vertical ratio:≥80%

Ultrasonic testing: GB/T 4162-2008 Grade A

Physical properties tempered to 44-50HRC

|

Temperature ° C

|

25

|

400

|

600

|

|

Density kg/m3

|

7820

|

7700

|

7600

|

|

Elastic modulus

MPA

|

210000

|

180000

|

145000

|

|

The coefficient of thermal expansion starts at 20 ° C per ° C

|

一

|

12. 7xl06

|

13. 3xl06

|

|

Thermal conductivity coefficient

W/m°C

|

-

|

31

|

32

|

Mechanical properties at room temperature

|

Hardness HRC

|

52HRC

|

45HRC

|

|

Tensile strength Rm

|

1820Mpa

|

1420Mpa

|

|

yield strength

RpO. 2

|

1520Mpa

|

1280Mpa

|

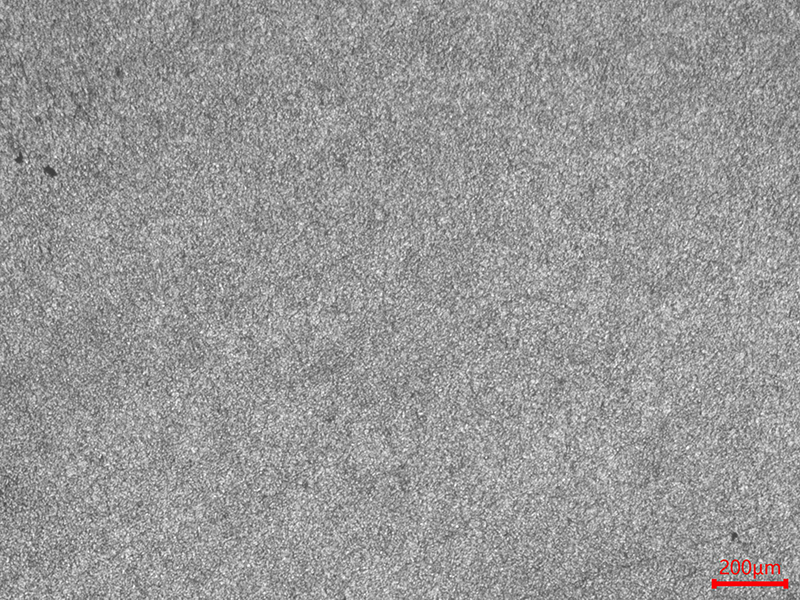

Figure 1 Microstructure 50 X

Figure 2 Microstructure 500 X |