|

TC8407(MCH13R)It is a high-performance hot work mold steel developed by steel mills using the latest research and development process technology. This special process technology results in high material purity, ultra-fine grain size, and a fine and uniform structure. Its various technical indicators have reached the advanced level of similar high-end mold materials abroad, and the material performance is excellent and stable; It has good resistance to thermal cracking, thermal wear, and plastic deformation, which can greatly improve the service life of molds. It is an excellent mold material that can replace imported hot work mold steel, especially suitable for small and medium-sized molds.

Can be widely used

Die casting molds for aluminum, copper, zinc and other alloys

Hot forging molds for various metals

Extrusion mold

| Chemical composition and other indicators |

|

C

|

Si

|

Mn

|

Cr

|

Mo

|

V

|

p

|

s

|

Other elements

|

|

0.36-0.40

|

0.8-1.2

|

0.15-0.5

|

5.0-5.5

|

1.3-1.5

|

0.9-1.1

|

≤O.015

|

≤O.003

|

Not yet announced

|

Hardness: Soft annealing ≤ 225HB

Non metallic inclusions: Class A, B, C, D ≤ Grade 0.5

Grain size: ≥ 9 levels, normal value 10 levels

Annealed microstructure:~A2,~B1

U-shaped impact toughness value (at room temperature): ≥ 38J

Horizontal to vertical ratio: ≥ 80%

Ultrasonic testing: GB/T 4162-2008 Grade A

Physical property tempered to 44-46HRC

|

°C

|

25

|

400

|

600

|

|

kg/m3

|

7820

|

7700

|

7600

|

|

Elastic modulus

MPA

|

210000

|

180000

|

145000

|

|

The coefficient of thermal expansion starts at 20 ° C per ° C

|

一

|

12. 7xl06

|

13. 3xl06

|

|

Thermal conductivity coefficient

W/m°C

|

-

|

31

|

32

|

Mechanical properties at room temperature

|

Hardness HRC

|

52HRC

|

45HRC

|

|

Tensile strength Rm

|

1820Mpa

|

1420Mpa

|

|

yield strength

RpO. 2

|

1520Mpa

|

1280Mpa

|

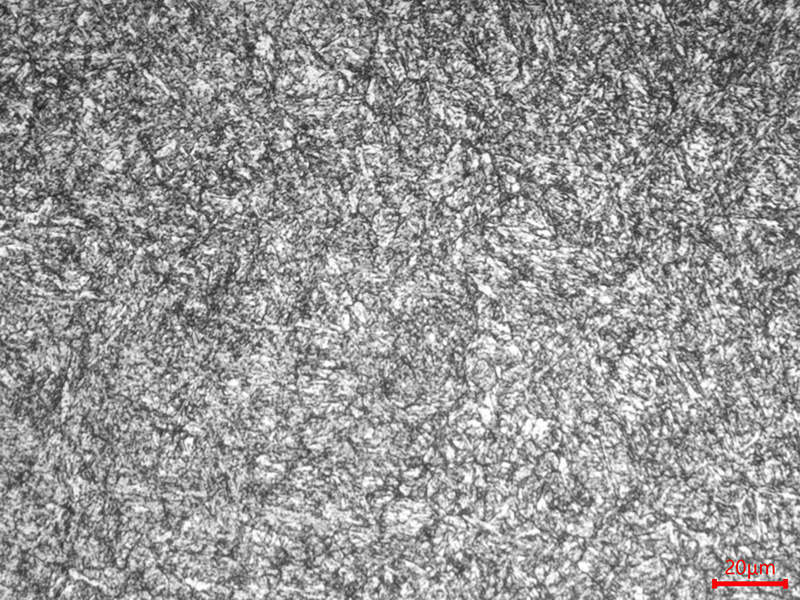

Figure 1 Microstructure 50 X

Figure 2 Microstructure 500 X |