|

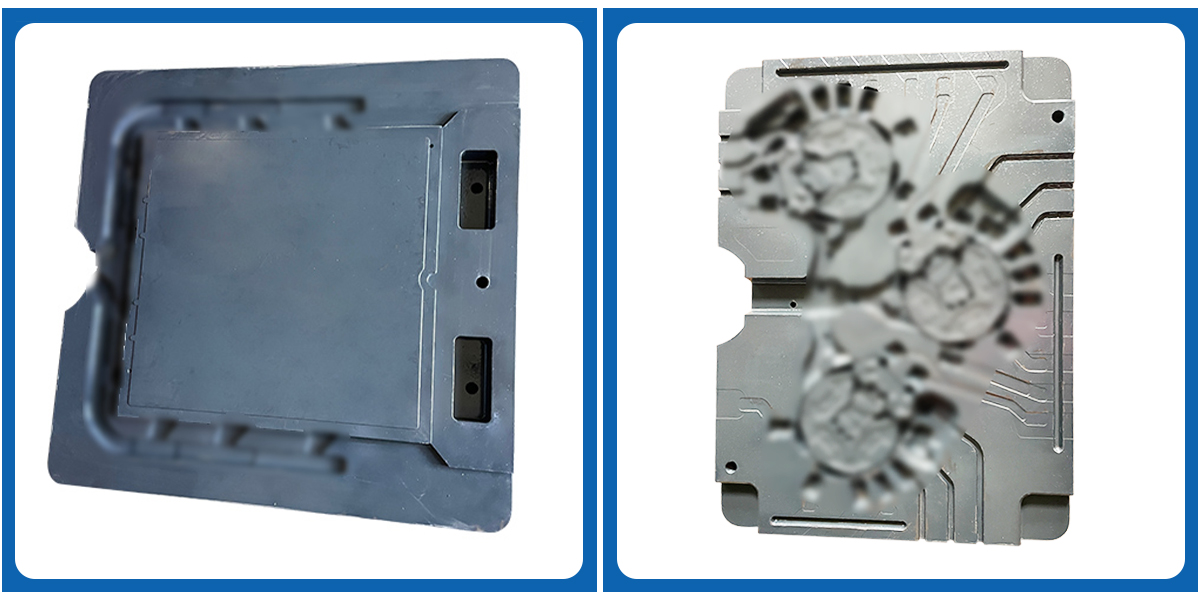

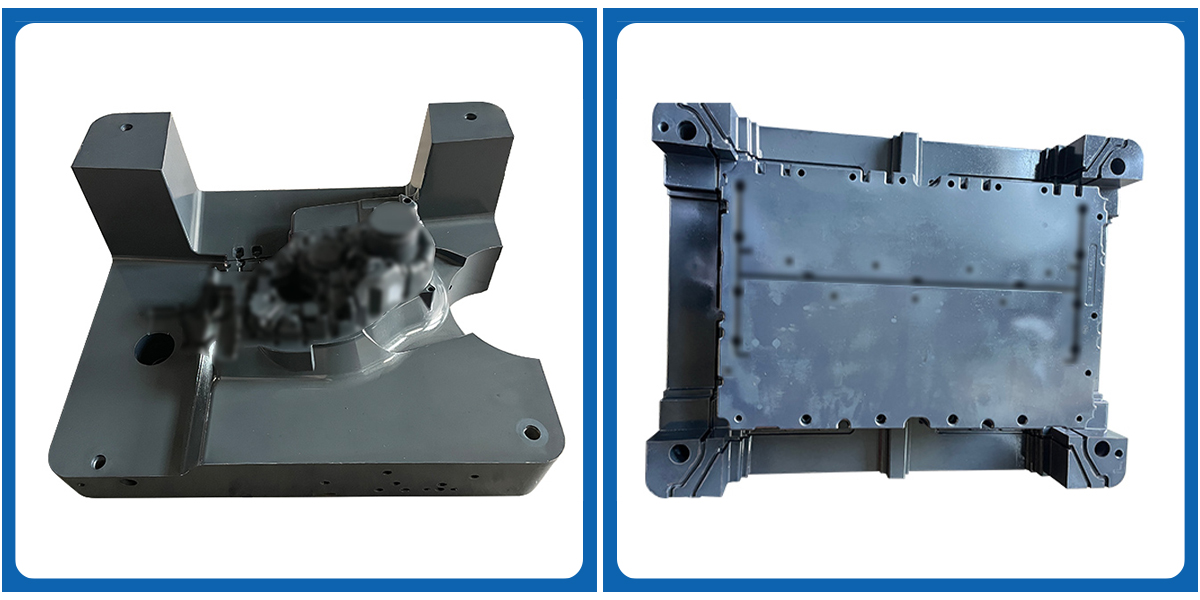

Nitridation is the process of infiltrating nitrogen atoms into the surface of a metal workpiece through special control. Nitriding treatment can effectively improve the thermal fatigue resistance of molds, enhance the wear and corrosion resistance of mold surfaces, and when combined with surface strengthening, can exponentially increase the service life of molds. Die casting molds and casting molds can significantly improve surface quality, delay the generation of surface cracks, enhance surface resistance to erosion and corrosion, have good demolding effects, and increase lifespan by about 50-80%. After surface nitriding treatment of hot forming molds, the wear resistance is significantly improved, and the mold life is increased to about 200-300%. After surface nitriding treatment of hot forging molds, the service life is increased to about 50-100%.

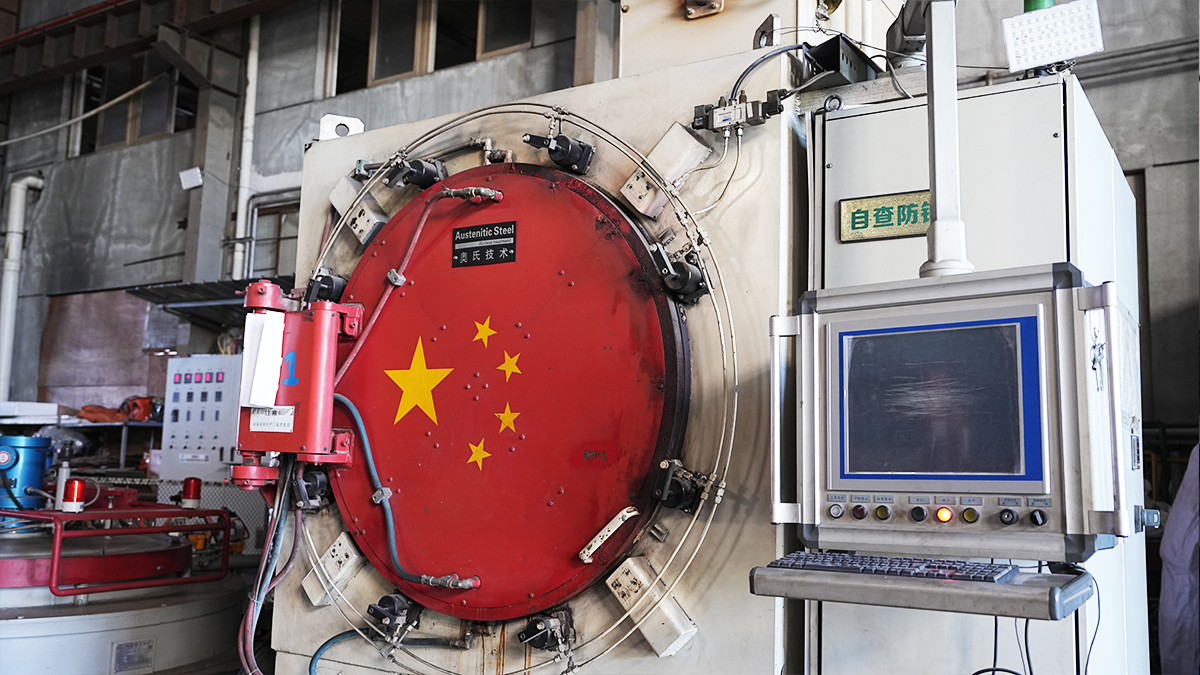

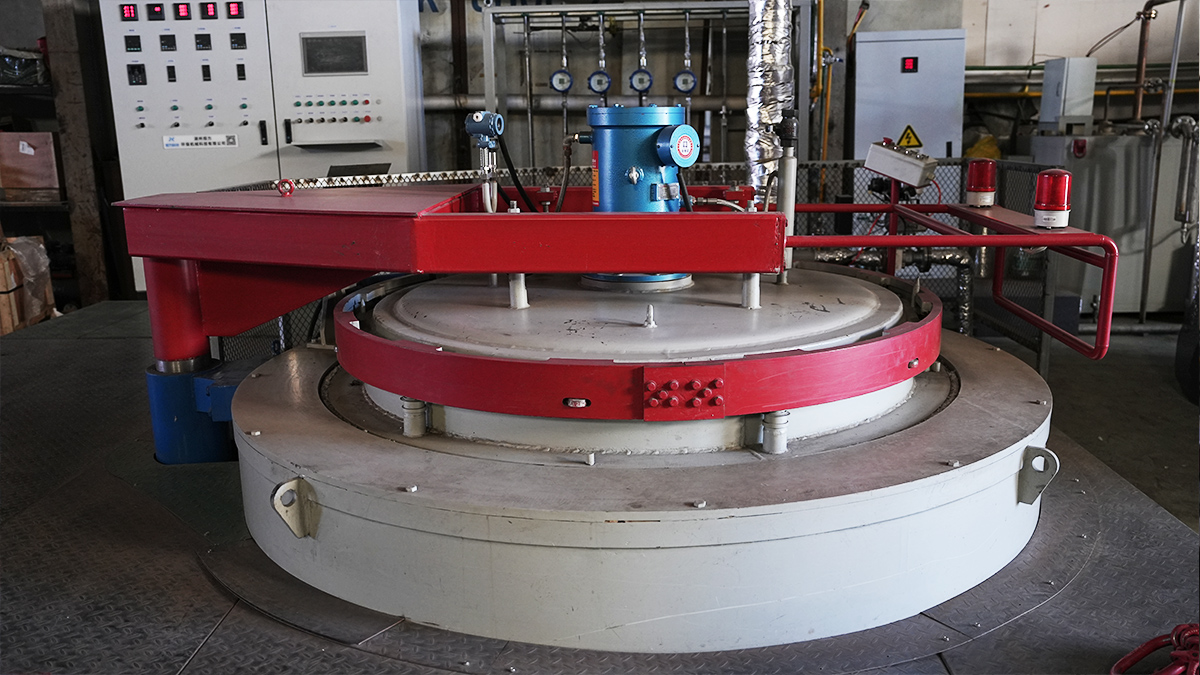

Our company's vacuum nitriding furnace is designed using German technology and customized according to the actual nitriding process requirements. Equipped with advanced and reliable automatic control systems, it achieves stable, economical, and efficient controllable nitriding treatment, precise control of the nitriding layer, and real-time recording.

(1) Equipped with a hydrogen probe (German STANGE), providing a basis for precise control.

(2) All gas flow controls are controlled using a German quality flow controller, which has the characteristics of fast response and stable speed. It can respond to monitoring feedback in a timely manner and adjust the atmosphere inside the furnace.

(3) Configure an NH3 cracker to regulate the atmosphere inside the furnace during process control.

(4) The equipment has good operability and process reproducibility, and the control of the nitriding layer is determined by process parameters without being affected by the furnace loading, thereby ensuring the quality stability of different batches of workpieces.

(5) The equipment automatically records all process parameters and real-time curves for each furnace.

Equipment specifications:

1. One horizontal furnace, 600 * 600 * 900, with a load of 1.2 tons;

2. One well type furnace with a diameter of 1200 * 2200 and a load of 7.5 tons;

3. One well type furnace with a diameter of 1500 * 2500 and a load of 10 tons;

Equipment function: The equipment has the functions of soft nitriding, hard nitriding, oxidation, and protective atmosphere tempering.

|